Paint Protection Film specialists servicing Greater Toronto Area. Over 18 years in automotive industry.

Perfection is the motive,

Quality is the key.

gallery

For close-up shots of a full body custom PPF installation with wrapped corners and edges, click HERE.

Material

XPEL ULTIMATE PLUS is a U.S. manufactured film with 10 year warranty. Top competitor in it's market. Available in both gloss and stealth finishes. Click HERE to learn more.

Installation

Learn more about what sets custom installation apart from pre-cut, making it the only desired installation method HERE.

contact

For a quotation please call, text or email PPF MASTER using the contact icons below. Please include the year, make and model of your vehicle as well as a picture of the front of the car and let us know what would you like to protect. Packages vary from full front to full car protection.

© ppfmaster.to All rights reserved.

History

Paint protection film was first developed and used by the military on helicopter rotor blades and other sensitive parts of military transports that were often damaged by flying shrapnel and debris.

thickness

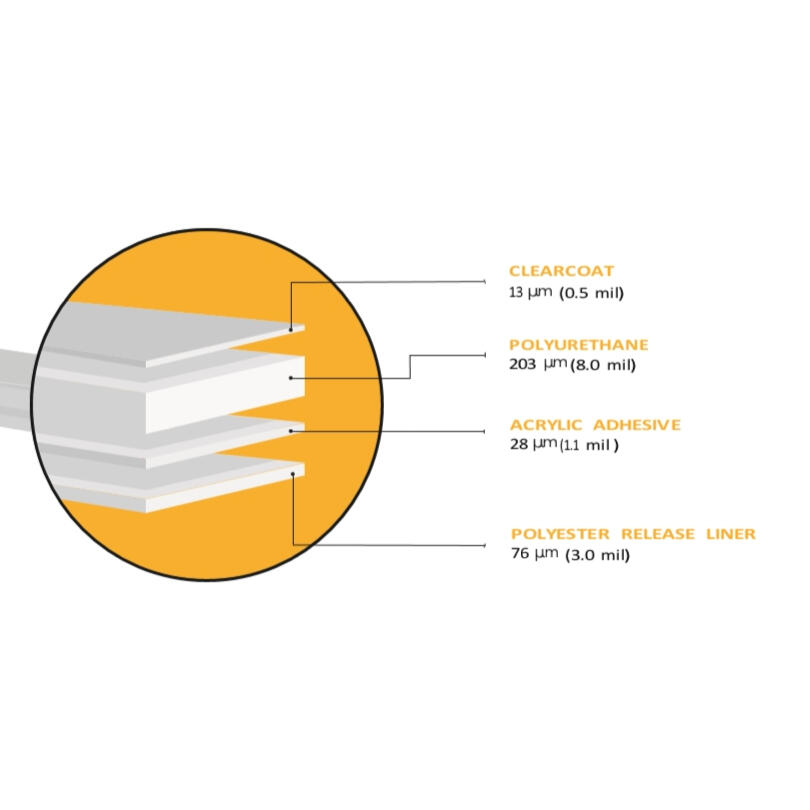

Unlike its competitors, XPEL film has an impressive 9.6 mil thickness, consistent of top protective clear coat, polyurethane base and acrylic adhesive.

stretch

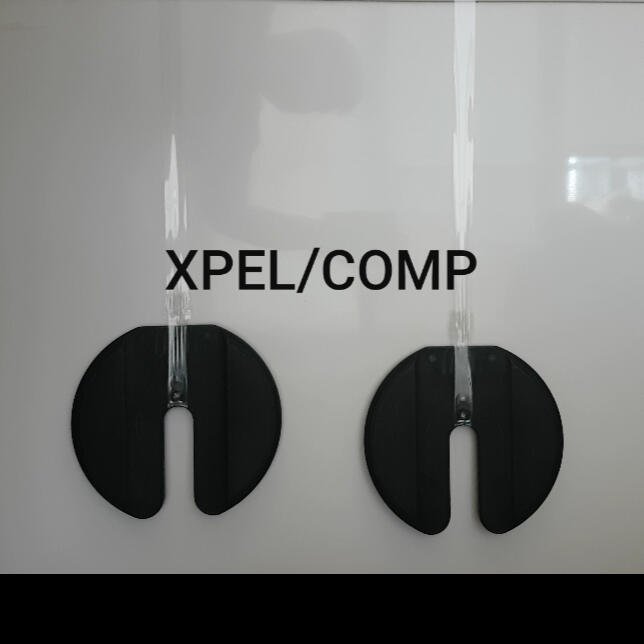

It's important to understand that a more stretchy film, sold by competitors, is easier to over stretch while installing, which lowers its protective capabilities by thinning out.

seeps into swirls

When installing, film's acrylic adhesive seeps into swirl marks and light scratches making it unnecessary to polish the application area before installation.

self-healing

Constructed from an elastomeric polyurethane, ULTIMATE PLUS will self-heal light scratches and swirl marks with a light heat application to the film's surface.

Hydrophobic abilities

XPEL's top coat is easy to maintain and requires nothing but soap and water to clean. Film's surface doesn't get dirty as fast subsequently your car will stay cleaner for longer and will be easier to wash.

warranty

Once installed, XPEL ULTIMATE PLUS is designed to last for a lifetime of the vehicle. Manufacturer warranty offers a 10 year coverage against yellowing, finish fading and film cracking, making it the longest warranty offered on the market.

For an official XPEL ULTIMATE PLUS video click HERE.

© ppfmaster.to All rights reserved.

In order to understand why custom film installation requires a more sophisticated skill set, one must first understand how a pre-cut installation, offered in 90% of city's shops and dealers works.

Normally a sheet of paint protection film is loaded into a plotter machine which pre cuts the film to an exact size of a panel that it is going to be applied to. Standard film application process requires the installer to fixate the film's edge approximately 1-2mm before the panel's curve begins, in turn, leaving the edge of the panel exposed.

The problem with this type of install is that in time, dirt will accumulate on the edges of the film making it very noticeable. Unfortunately with time the dirt cannot be removed anymore as it will seep into the film's adhesive, making the install look sloppy.

More over, depending on a cutting software used by the shop/dealer for machine plotting, some pre cuts will be off by as much as 5mm or more.

Luckily for the consumer, some paint protection film specialists will go the extra mile and learn the unique custom installation skill sets needed to provide you with an exceptional install that will make you happy for years to come.

wash

Application surface is washed and decontaminated to provide a clean area for the film to stick. Specially concentrating on panel edges and areas where material is going to be rolled to.

Clay bar

Surface is clay barred to ensure the removal of all the specs that ate their way into paint over time. A good example are brown dot rust spots left on the vehicle from metallic dust when transported by freight.

application

Custom application means applying the paint protection film in bulk peaces that are larger than the panel itself leaving excess material for rolling it over the panels' edges.

trim

Custom trimming aka "free hand" is trimming the applied material exactly where needed based on that particular panel, leaving no uncovered edges and protecting the panel throughout.

rolling behind edges

Method used only by seasoned installers as it requires the outmost perfection in this craft. Having the film stick and stay behind the panel's edge makes it seem as though there is no film installed.

corners work

An art on its own! Corners are the first give away that the film is installed on a vehicle. Due to this skill's complexity, corner work is one of the toughest installation skills to master.

tucking under ruber

Tucking the film edge under the rubber is another excellent trick used by specialists to ensure that the entire panel is covered. It's mainly used on roofs of the vehicle protecting the front facing edge from road debris.

post heating

To ensure the installation's longevity, all film edges are post heated ("sealed") using various heating methods depending on location and ease of reach to the film's edge.

© ppfmaster.to All rights reserved.

Mercedes Benz GLE63 AMG

Full body STEALTH conversion from gloss paint to matte finish paint protection film.

Ferrari f12 TDF

Full body gloss paint protection film.

Lamborghini Huracan

Full body STEALTH conversion from gloss paint to matte finish paint protection film.

Lamborghini Huracan

Full body gloss paint protection film.

For more photos and videos click HERE.

© ppfmaster.to All rights reserved.